One of the most interesting phenomena of any product, promoted and sold, is the illusion of superior product exhortations. My stuff is better than your stuff. This, of course, is a core function of the sales world – to display an item, device or tool that creates a better world.

This is grandly exploited in the world of sports-specifically, high performance racing. While most spring manufacturers produce a product based on a blueprint or spec sheet that calls out all the pertinent data (hard science), most spring makers will tout their capabilities in the world of reality. In other words, they do not spin their product as producing an outcome that is overtly untrue or exaggerated because physics and math (the natural world) are somewhat predictable.

However, keep in mind that auto racing is based on one premise… Competition. This implies winners and losers, with winning being the preferred outcome. The whole world of advertising is steeped in gaining an edge over a competitor. However, with something as highly engineered as a competitive racer, of all items capable of being marketed and sold as a superior solution are promoted with great skill and ambition.

After being exposed to high performance for over 20 years, I can testify that springs are an integral part of a functioning suspension that can create winners if set up correctly. Since automobiles, as with any other engineered mechanical product, are only as good as their weakest link, springs have high expectations of consistency in their dimensional traits. Many producers tout superior material as their particular “edge”.

As much as I have my opinions on the various superior materials being claimed by some manufacturers, I also know that all materials must be certified. There must be a detailed listing of the chemical composition, mechanical properties, metallurgical requirements, workmanship, tolerances, and appearance. Without a specification that clearly calls out all those properties comma how would anyone know what they were buying?

Any reputable spring manufacturer will be buying their spring steels to certified call outs, such as ASTM. If you have questions about the steel that any spring is made from, ask the supplier as to the certification used. This information can then be studied and gives the buyer the ability to question any manufacturer as to what material cert is being used by the material. This data, of course, can be used to query any supplier since most spring companies buy their steels from the same suppliers that certify to the same specifications.

No spring company will be able to buy custom, proprietary materials without a high investment and purchase arrangement. Even then, the “edge” that it creates is likely not worth the elevated cost of the product. Don’t hesitate to ask suppliers who make claims of superior anything, as to what material certification is being used.

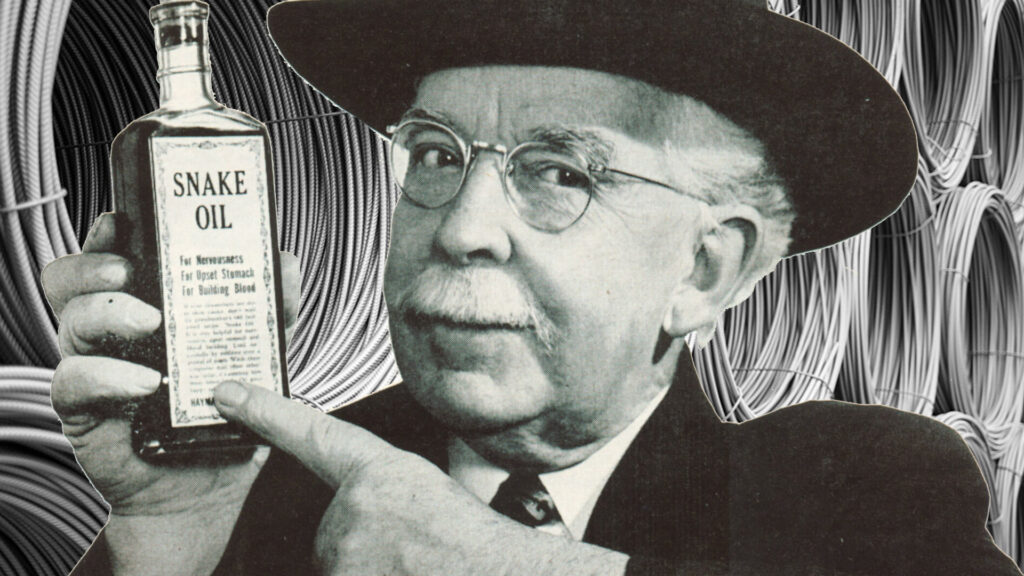

It’s your right and you can use that information to ask any supplier. You can freely listen to the marketing promotion but just a little homework can pay you back with better choices with less time invested. That… Is an “edge” that counters the hyperbole that snake oil can obfuscate.

This article was written by Randy Deford, who held the Engineering Manager position at Mid-West Spring and Stamping, which is Landrum Performance Springs’ parent company. The article was printed in the Fall 2020 issue of Wire Forming Technology International magazine. Mr. DeFord has since retired.